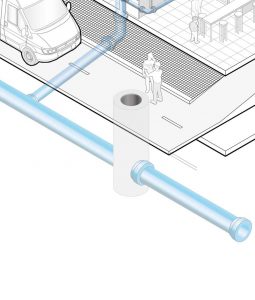

lineTEC main and industrial sewer rehabilitation

DN 200 – 700 (8” – 27,5”)

Pipes with large nominal diameters are often rehabilitated with glass liners in UV-curing. Up to a diameter of DN 700, rehabilitation with epoxy resin-soaked felt liners or felt-glass liners is economically competitive and also offers several advantages.

Thanks to their high flexibility, the liners adapt perfectly to the old pipe, even in bends and with slight dimensional deviations. In addition, it is possible to rehabilitate pipes with epoxy resin even if groundwater infiltrates. The resin does not react with water, usually sticks to the pipe wall and has such low shrinkage that backflow is no problem.

In addition to the standard range, lineTEC also supplies tailor-made products according to customer requirements.